New cleanrooms for

Electron-Beam nanoLithography (EBL)

based on Scanning

Electron Microscope (SEM)

Documentation

Building

Documentation

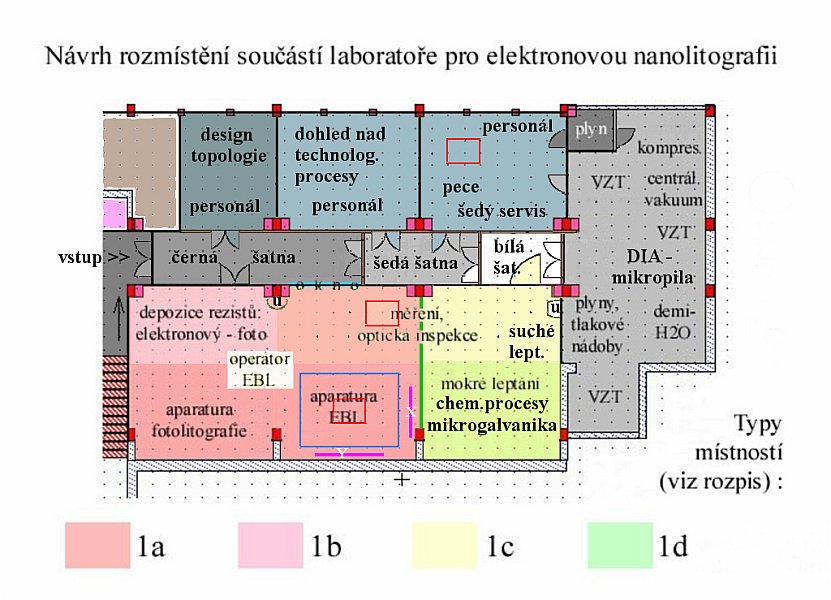

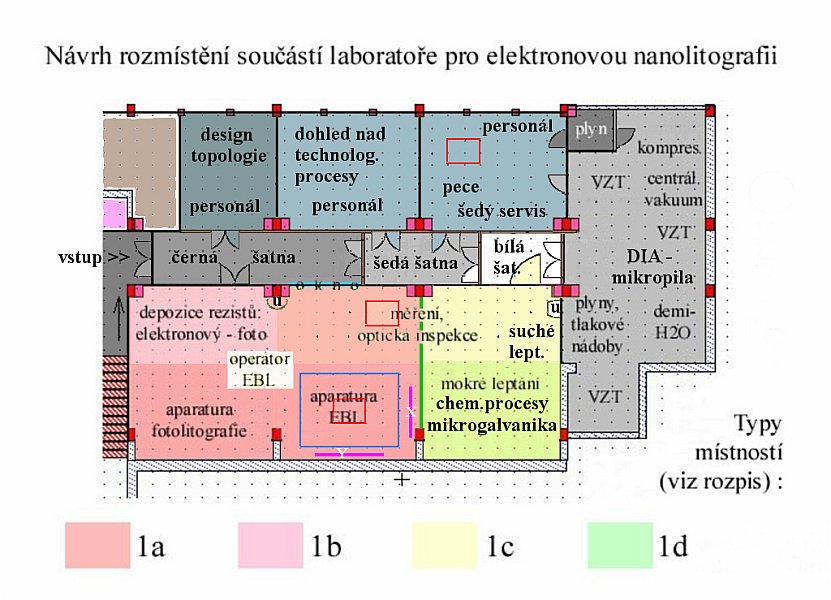

Outlook of the laboratory (version 0530 = MMDD):

A grid of 0,5 meter pitch on background of this as well as of some other drawings.

Room types:

- class 100 : space for the EBL column (temperature stabilized to +/-0,5°C),

space "1b" (exhaust of 1200m3/hour),

- class 1000 : other parts of the cleanroom "1a",

- class 10000 : area "1c", area "1d"

(exhaust of 2400m3/hour)

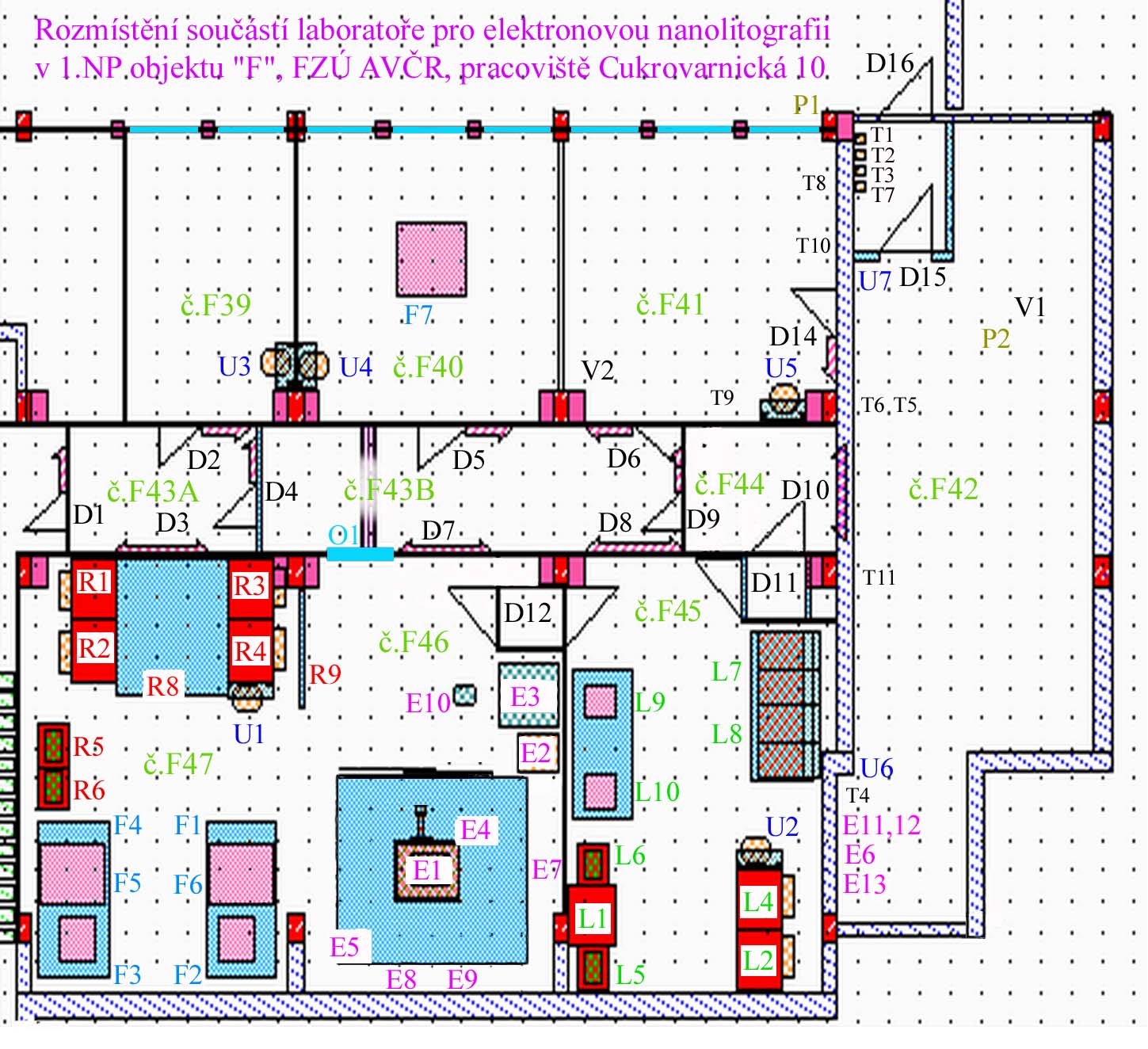

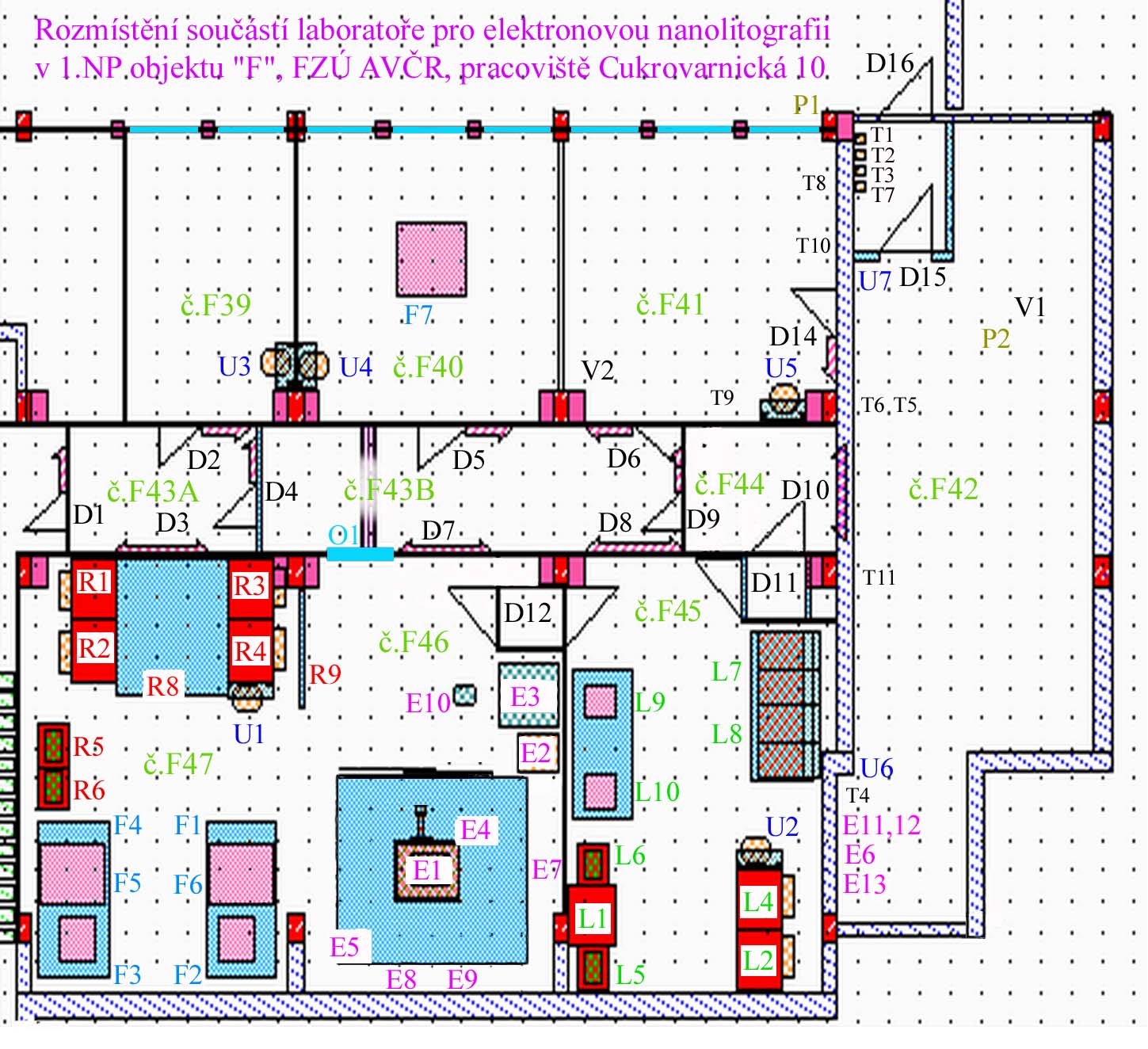

Position of (enumerated) parts of the laboratory (version 0703):

Labeling (and characteristics) of individual rooms:

room No.F39 - "black" office (staff - topological design of structures),

room No.F40 - "grey" office (staff - technological processes supervision),

room No.F41 - "grey service" (staff - maintenance, part of technological equipment),

room No.F42 - "grey" room (HVAC, part of technological equipment),

room No.F43A - "black entrance" (entrance area),

room No.F43B - "grey gowning area" (first gowning),

room No.F44 - "white gowning area" (final gowning),

room No.F45 - cleanroom of class 10000 (wet- and dry- etching),

rooms No.F46+F47 - cleanroom of basic class 1000 comprising zones of class 100 (lithography)

Area of electron-beam lithography + microscopy (EBL/SEM):

E1 - basic unit (column)

E2 - rack comprising supply and control units

E3 - control panel EBL/SEM

E4 - antivibrational block (for EBL/SEM)

E5 - laminar zone (+/-0,5°C, class 100)

E6 - roughing pump

E7 - coil X (of spurious magnetic fields compensation system)

E8 - coil Y ( - " - )

E9 - coil Z ( - " - )

E10 - EBL/SEM operator seat

E11 - EBL/SEM system thermostat unit

E12 - unit of electron lens thermostat (stabil. to 0,1°C)

E13 - EBL/SEM control UPS

|

|

|

Area of resist processing (room No.F47):

R1 - chemical flowbox (electron resist deposition)

R2 - chem.flowbox (electron resist development)

R3 - chem.flowbox (photoresist deposition)

R4 - chem.flowbox (photoresist processing)

R5 - box for resists (exhausted)

R6 - box for developers, etc. (exhausted)

R7 - storno

R8 - laminar-flow area, class 100

R9 - anti-static curtain

|

| |

|

|

Photolithography and optical microscopy area (room No.F47):

F1 - hanging laminar-flow unit (optical microscope)

F2 - hanging laminar-flow unit (diagnostics)

F3 - hanging laminar-flow unit (contact aligner)

F4 - hanging laminar-flow unit (projectional aligner)

F5 - antivibrational block (for contact aligner)

F6 - antivibrational block (for projectional aligner)

|

|

|

Wet- a dry- etching cleanroom (room No.F45):

L1 - fume hood (corrosionless construction)

L2 - chemical flowbox (wet etching - acids, bases)

L3 - storno

L4 - chemical flowbox (wet etching - organics)

L5 - box for anorganic chemicals (exhausted)

L6 - box for organic chemicals (exhausted)

L7 - dry-etching equipment (PE)

L8 - dry-etching equipment (RIE)

L9 - hanging laminar-flow unit (optical microscope)

L10 - hanging laminar-flow unit

|

| |

|

|

Technical background (rooms No.F41 and F42 - HVAC):

T1 - compressed gas (O2)

T2 - compressed gas (CF4)

T3 - compressed gas (spare position)

T4 - equipment for pure water preparation

T5 - oil-free compressor

T6 - pump and central vacuum-reservoir

T7 - compressed gas (forming gas Ar+5%H2)

T8 - oven

T9 - die saw

T10 - thin-layer deposition equipment

T11 - LN2 -> gaseous nitrogen generator

|

|

|

Some other parts:

F7 - antivibrational block (room No.F40)

O1 - check-window to the cleanroom No.F46

P1 - heating gas input valve (on the outer wall)

P2 - gas-heating for the input HVAC unit

U1 - washer incl. safety shower (room No.F47)

U2 - washer incl. safety shower (room No.F45)

U3 - washer in room No.F39

U4 - washer in room No.F40

U5 - washer in room No.F41

U6 - washer + sink in room No.F42

U7 - washer + sink in room No.F42 (maintenance)

V1 - HVAC units (according to the HVAC design)

V2 - main computer for HVAC measur.&control

|

"Quasi-3D" aerial views of the laboratory (the door D10 and some other details are not shown in these

views):

|

|

Orientation of the central EBL unit vs the beam blanker |

|

Description of the magnetic field cancelling system

here.

Building

Building process related to some parts of the laboratory

(see captions of individual thumbnails displayed):

Last updated:

Mar 12, 2007

Back to the home page of the laboratory

Czech

version

Czech

version